“Monozukuri” – in Japanese, does not simply mean “to make things” but embodies the essence of craftsmanship, technical expertise, dedication, and pride of the maker. At ISUZU, this philosophy has been inherited and evolved into ISUZU Monozukuri (IM) – the method of realizing the vision “Moving the World – for You.” It represents not only a commitment to deliver reliability in every vehicle but also a pledge to create value for customers and society.

The Core of IM

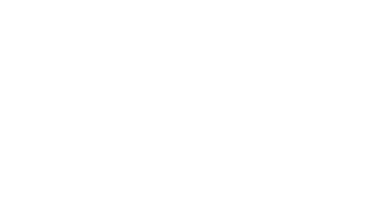

The core of ISUZU Monozukuri (IM) has been inherited and developed from the philosophy of the IMM system – ISUZU Manufacturing Management: “Continue making better products.” By following the principle of not repeating the same mistakes again (quality defects), customer satisfaction is enhanced. In addition to focusing on technology and manufacturing processes – “Monozukuri,” ISUZU Vietnam also places special emphasis on human resource development – “Hitozukuri.” This helps build a workforce that is proactive in learning, thinking, and acting, thus establishing a safe, lean factory where production processes flow run without interruption.

Mr. Lam Nhu Huy – Head of IM Promotion at ISUZU Vietnam

To realize the philosophy and objectives of IM, the role of system leaders is crucial. Mr. Lam Nhu Huy – Head of ISUZU Monozukuri Promotion belongs to the Quality Management Department, Production Division at ISUZU Vietnam, who is primarily responsible for managing the production and quality systems at the plant. Mr. Huy is among the very few recognized as an IM Instructor, with currently only around 60 individuals across the entire ISUZU Group worldwide holding this prestigious certification.

Mr. Huy Awarded the Prestigious IM Instructor Certificate

Mr. Huy shared that one of the most impressive aspects of IM is “top-bottom” mechanisms – the harmonious combination of “top-down” management thinking with “bottom-up” on-site improvement activities, which enhances problem-solving capabilities at the production site. For example, “Asakai”, the daily morning quality check meeting, which allows sections to share information, propose solutions, and ensure smooth, seamless operations throughout the day without any problems.

In addition, based on the principle that “People are still likely to make mistakes no matter how hard they strive,” IM established its quality management system on a “spiral-up” model with three steps: “do not pass defects” “do not make defects,” and “cannot make defects,” all grounded in the fundamental step of “standardized production.” This ensures defective products are prevented from reaching the market or customers, aiming at the ultimate goal of 100% quality assurance.

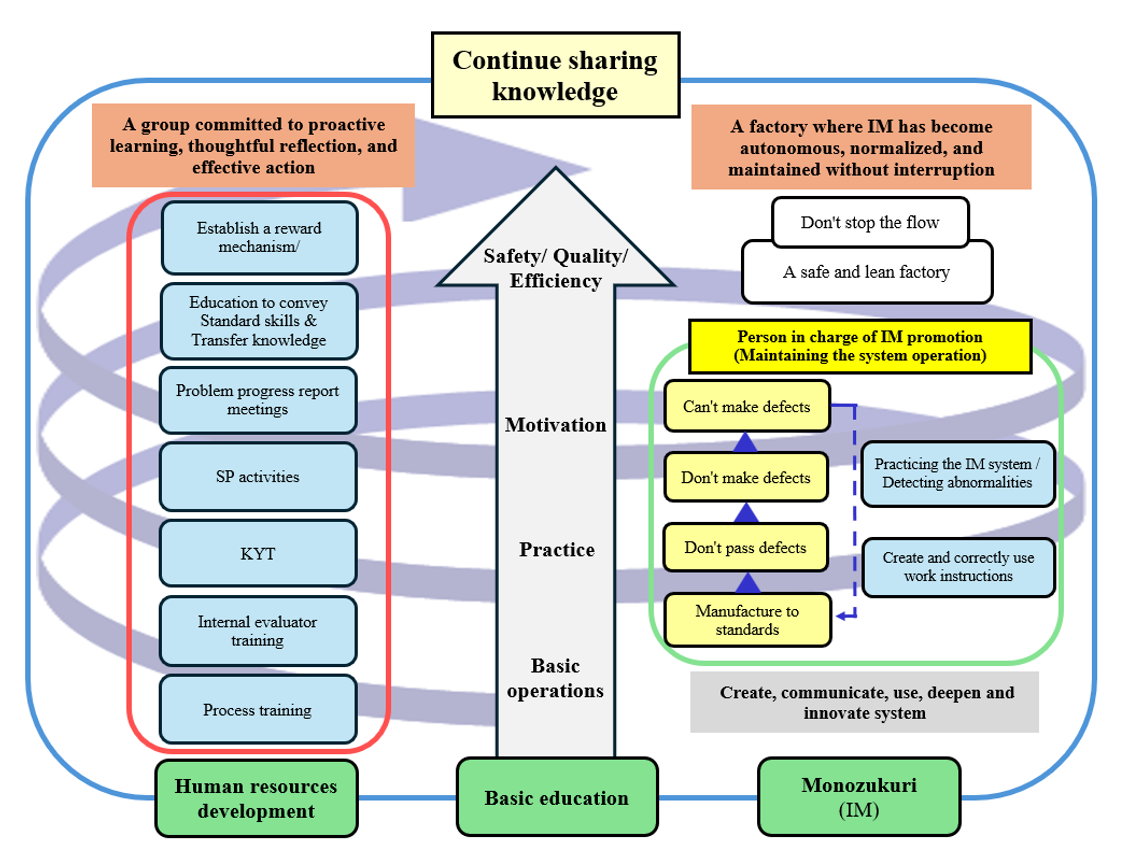

Furthermore, the system adheres to the principle of separation of powers in quality management, in which the production engineering, production and quality control (inspection) operate independently while monitoring one another – similar to the Legislature, Executive, and Judicial branches in a government system. This mechanism assures customers that every vehicle leaving the factory undergoes the most objective and rigorous quality control, delivering absolute peace of mind.

Development Roadmap

The implementation and development of IM at ISUZU Vietnam have been carried out through several key steps. As the first step, the IM system from ISUZU Japan was adopted and adjusted to fit the production conditions at ISUZU Vietnam. Accordingly, a dedicated set of standards was approved and officially issued on July 1, 2025. In the following step, training sessions have been organized to disseminate IM system knowledge across all personnel in the production division. A group of nine internal evaluators are being trained to become key drivers in carrying out daily IM activities at the factory. By the end of 2026, ISUZU Vietnam is expected to undergo evaluation and receive IM certification from IML (ISUZU Motors Limited) once the application of standards and compliance with IM system requirements are fully achieved.

IM – A Management System and Philosophy for Sustainable Development

ISUZU Monozukuri is the perfect integration of a lean manufacturing management system that delivers superior product quality with a human development philosophy that builds a flexible workforce, always ready to adapt to environmental changes and the increasing demands of customers. At ISUZU Vietnam, we continuously strive toward a safe, innovative, and efficient factory to deliver the highest quality products to our customers.

-ISUZU Vietnam-